|

This much important mission gave to this often small part of the ammunition one of the most important roles for the correct operation of all the giants, guns and projectiles, that are spoken about in the other pages of this website.

The fuzes that can still be found nowadays in the ploughings, embedded in earth or chalk and half destroyed, are remnants of precision mechanics and pyrotechnics systems... For a good understanding of the explanations and diagrams of the section 'WW1 fuzes', one might want to take some time to familiarize himself with some technical concepts of WW1 fuzes mechanics and pyrotechnics, one of the impressive examples of the human creativity at the service of crime and horror...

Several types of fuzes were in use in 1914-1918. They can be roughly categorized on the basis of the timing needed for triggering the shell explosive charge :

These parts of the artillery ammunitions, designed to trigger the burst at a defined part of the shell trajectory or at impact despite severe conditions before the shell was fired (humidity, shocks, corrosion, ...) and during its shooting (huge accelerations and decelerations, high heat, rapid spin, violent shocks) were remarkable high precision mechanisms. A fuze was also supposed to present all the safety guarantees for the gun crews : it had to be designed in order to sustain uncareful handling during transportation, uncontrolled storage conditions, and the violent acceleration of the shooting start in the tube without causing premature explosions, likely to destroy guns and servants... This additionnal specification added to the fuzes design complexity. It is interesting to note that the trend of the pre-war was to develop more and more sophisticated fuzes, while the war experience, new types of shells and artillery techniques, and war economics induced at the contrary the use or more and more simple fuzes. |

|

The embarked explosive charge of the fuze could be strong enough to trigger the explosion of the main charge of the projectile when filled with gun powder, but with the very powerful modern and more stable chemicals for high explosive shells (for example molten TNT or mélinite main charges), the fuze charge was only igniting a 'detonator' (also called 'intermediate charge' or 'primer') that had sufficient explosive energy to cause the shell detonation. |

|

| French detonator | German Dopp Z 96 fuze assembled on a HE shell, showing the primer attached to the tail before mounting on the shell top gaine | |

| French 24/31 Typical french high explosive shell pyrotechnic line : from the left to the right, the fuze itself, the adaptator screw ring, the small primer usually screwed on the fuze tail, and the bigger intermediate detonator often mounted into the shell body |

Fuzes were (and still are...) dangerous pieces of equipment, designed to create a flame, an explosion or even a detonation on a shock or when ignited. Safety devices were necessary to ensure they would not act this way elsewhere than in enemy territory, just when they were wanted to do so. Springs and pins : the basic arming devices Stirrups and ramps : inertia arming systems : Pyrotechnic arming system Centrifugal force arming system The centrifugal force effects were used in numerous fuzes or detonators safety devices, using different principles, as seen in the following examples :

Uncareful handling during transportation, accidental falls during manipulation, surrounding enemy shelling shockwaves were only examples of so many things that could frequently happen to the fuzes in an usual war environment before their use. Military engineers had to invent safety devices that would inert the fuzes before they were assembled to the shell and shot by the gun.

But another danger existed within the gun itself at the very first instants of the fuze active life : the brutal acceleration of the departure could also cause premature triggering of the fuze and shell explosions still in the barrel, often destroying both the material and its servants... This was another reason for designing safety and arming techniques that would avoid such catastrophies.

Removing the safeties of a fuze is called 'arming'. This could be done manually while the fuze was still attainable, but had to be done automatically from the time it disappeared into the gun breech hole. The corresponding devices are many, and the following list is just intended to give an idea of their varieties, using pins, springs, centrifugal force or pyrotechnics.

French fuzes often included an auto-arming device, designed to remove a mechanical safety under the action of the shock of departure. This additional safety gave more guarantees than the basic safety spring that was then just kept for providing the in-flight safety, and allowed to avoid safety pins that could be dangerous if accidently removed in the heat of the moment, and were detrimental to the rate of fire since it added an additional operation from the firing crew.

These inertia auto-arming systems all had the same goal of keeping the graze pellet and the percussion pin out of reach of each other before the shot.

French most famous ones were named 'Robin' system and 'Peuch' systems.

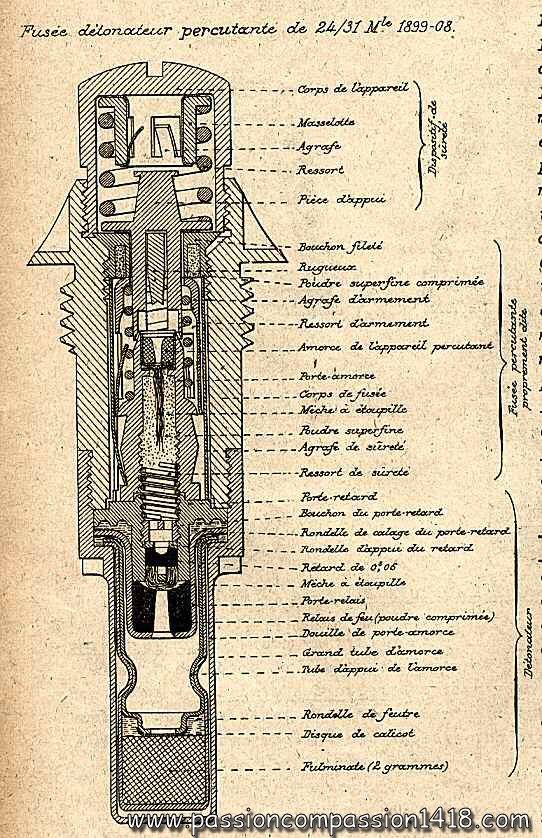

The Robin system has been widely used in French fuzes. One classical example is be the 24/31 Mle 1899/08 fuze

The wartime scheme at far left shows that fuze, using a Robin arming system for the percussion system in the tail and another kind of stirrup system in the top head mechanism ('Lejay' type) for an additional safety. The picture at left shows the remains of such a fuze that can be easily comparred with the scheme.

This mechanism was also used in other fuzes, including the time and percussion fuze 30/38 Mod 1884 and its numerous followers.

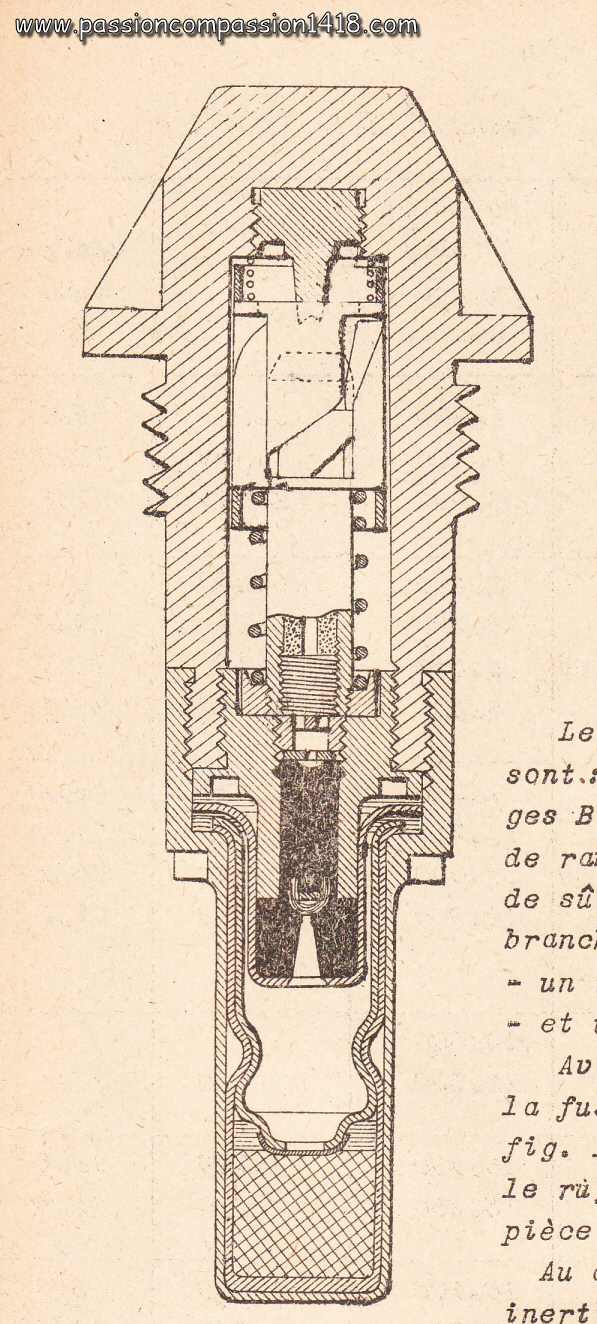

Scheme of the fuze in section.

Section of a french percussion fuze with inertia arming system.

A dismantled Budin fuze, ancestor of the Robin system, showing the percussion pin, the safety spring, and the starter-bearer equipped with a staple mechanism that had to be compressed by the departure shock energy in order to enter inside the inertia block.

Helicoïdal ramps ('Peuch') system

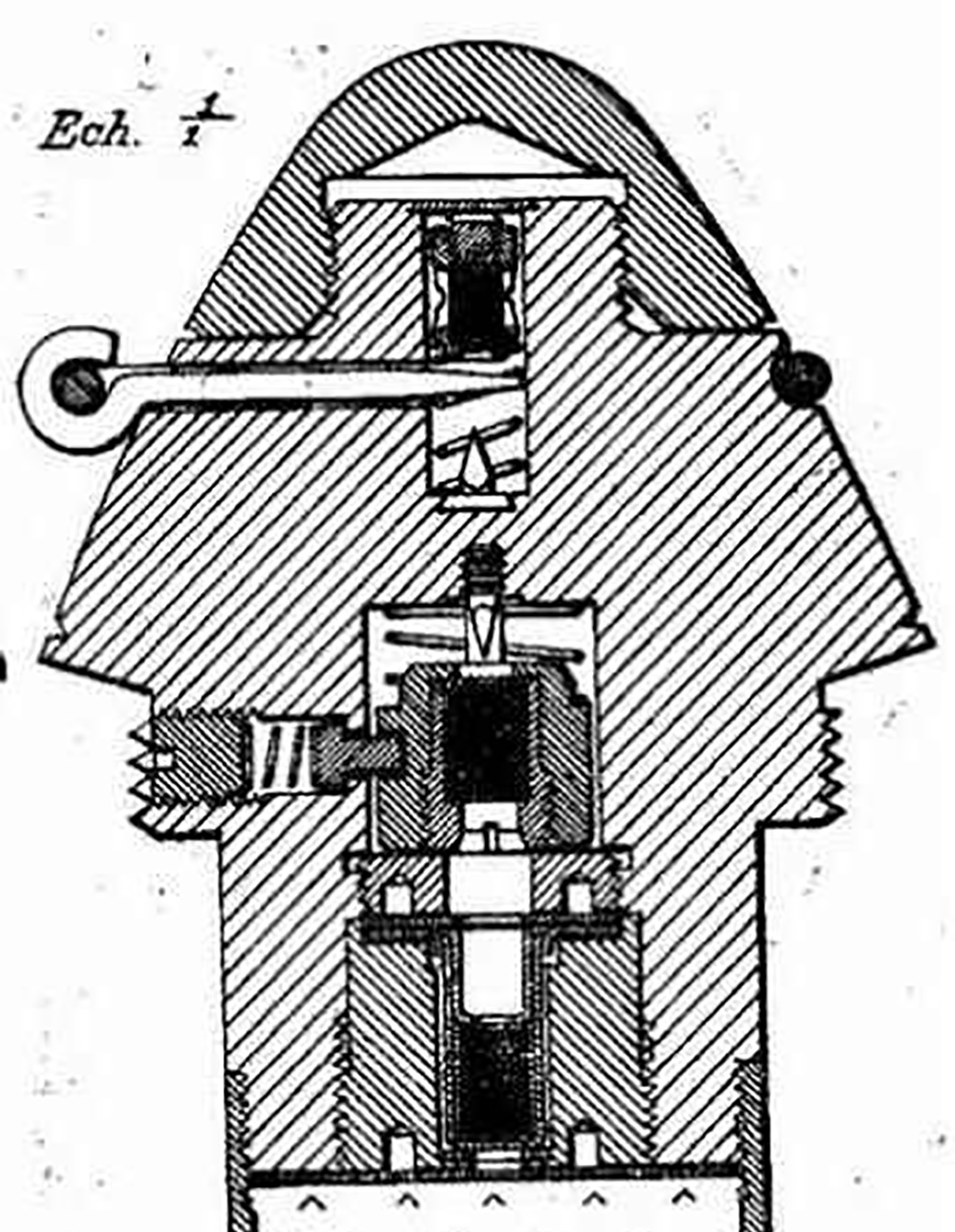

Another classical French auto-arming system was the helicoïdal ramps type invented by M. Peuch.

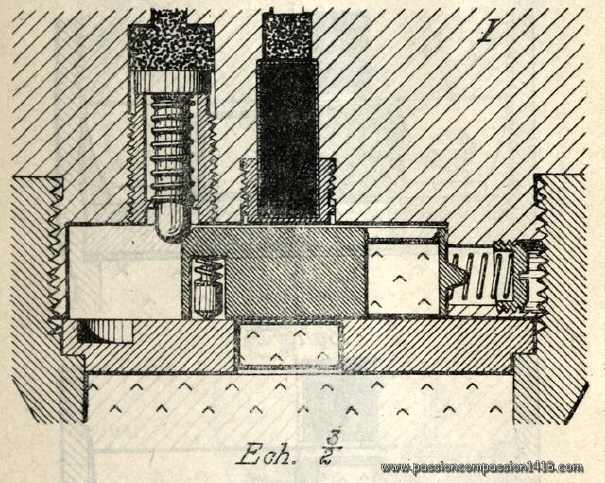

In this system first implemented in 1914 in the fuze 24/31 Mle 1914, and later in the mine-throwers fuze 24/31 Mod 1916, the accidental meeting of the percussion pin and the detonator cap was prevented by an intermediate cylinder that could shorten itself thanks to an ingenieus system of helicoïdal ramps.

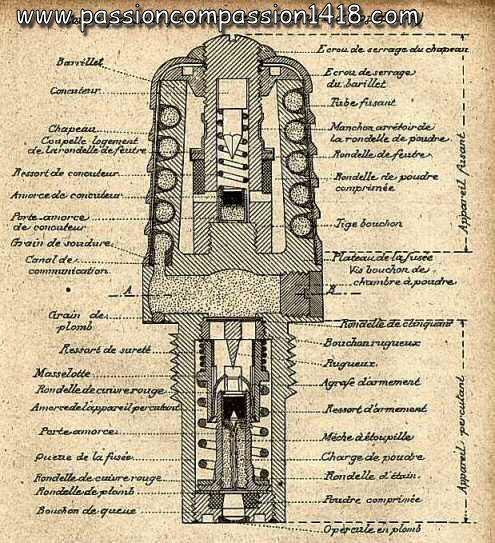

An alternative to the French inertia arming system was introduced by the German military engineers with the pyrotechnic safety. These devices were based on a blocking stem and gunpowder grain system.

This system was widely used in German percussion fuzes as well as in time fuzes. Its advantage was that it allowed to arm the fuze only after the full combustion of the compressed gunpowder grain, that is somewhere on the shell trajectory after leaving the gun barrel. On the other hand, combustion gasses needed some more machining in the fuze for the fumes vents and the necessary igniting system, adding to manufacturing complexity.

Wartime scheme of the KZ14 German percussion fuze, using the pyrotechnic safety system. One can see the system housed on the top of the fuze in two cylinders, one with the concutor, the other one with the compressed gunpowder grain and the stem, as well as the fume vent.

Cut through of a KZ14 fuze. Only the mobile concussion system is missing.

Section of the same fuze, showing the same mechanisms damaged by the explosion.

A completely different pyrotechnic safety system was integrated inside the medium and large minenwerfer fuze ZsumMW.

In these devices, the combustion of compressed gunpowder grains ignited at shot departure was needed to allow the action of springs opening metallic jaws that were blocking the movements of the main percussion system at rest.

Another classical way of arming fuzes after the departure of the gun was to take the opportunity of the spin movement of the shell when fired with a rifle bore tube. This rapid movement gave way to very high centrifugal forces in the shell and fuze.

That effect was mainly used by German fuzes and some British or French ones. One of the specificities of such a phenomenon was that the centrifugal force remains applied to the shell during the whole trajectory, while the inertia needed for stirrup mechanisms was only available during the acceleration par of the trajectory, that is inside the gun barrel.

The centrifugal effect gave way to various systems, and was also used for detonator safety systems.

Centrifugal safety locks

were the first and simpler devices using the centrifugal force created by the shelle spin. They consisted basically in a radial rod locking the movements of the percussion graze pellet and maintained at locked position at rest by a small spring.

These devices could exist in a single or twin lock solution, for instance to block the graze pellet of the HZ14 Fliehb. percussion fuze , or the percussion rod of the EHZ17 super-quick fuze

Unwinding centrifugal safety

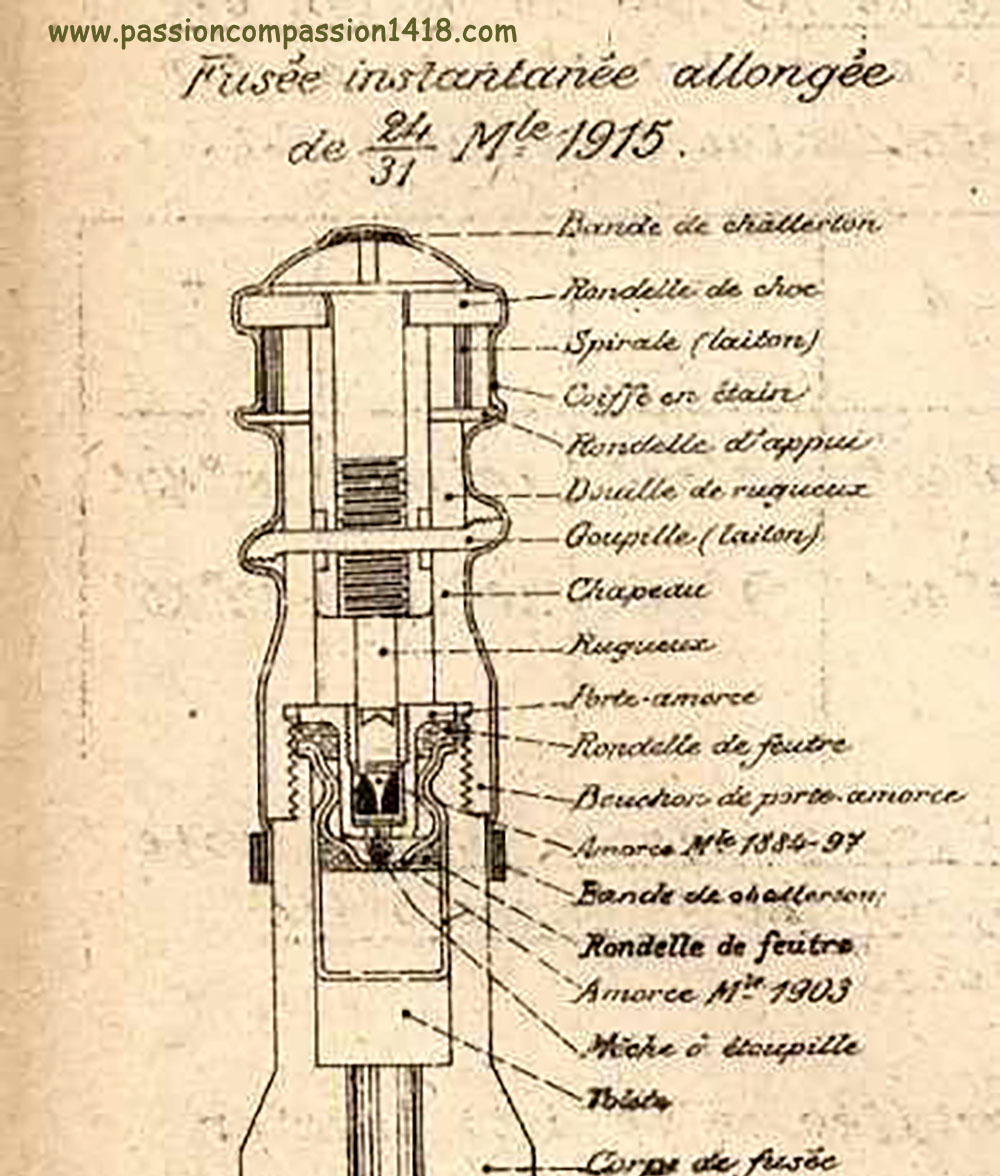

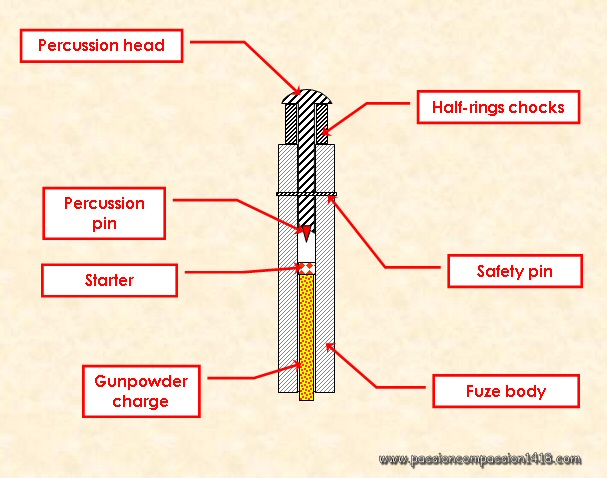

This simple but ingenious system was used almost exclusively in the French fuzes I.A. model 1915 and I.A.L. model 1916 and is known as the ‘Lefèvre system’. It consisted of two safety half-rings preventing the recoil of a percussion pin, connected to a fabric and brass spiral wound around the half-rings and ending in a steel weight.

During its journey through the tube, acceleration would tighten the coil to prevent premature bursting, but upon exiting the tube, this would cease and the centrifugal force created by the rotation of the shell would unwind the coil and eject the half-rings.

Rotating bolts safety locks

seems to have been introduced first in the German navy fuzes, then used in many army ammunitions.

The device was made of a number of rotating bolts on eccentric pivot aligned in circle, as a photographic diaphragm. In closed position at rest, the bolts would rotate under the effect of the centrifugal force, opening a way in the middle. This was often cleverly designed so that the 'petals' rotation was not allowed while the projectile was accelerating in the barrel.

This system was able to block either a percussion system graze pellet movements, or the percussion rod of super-quick percussion fuzes, such as this GRZ16 and this GRZ17 fuzes

Sliding drawer safety locks

was uniquely dedicated to prevent the flame from the fuze to reach the tail detonator.

This was therefore an additional safety device, often adding to one of these described above, should they fail in their mission. The design was based on a sliding polygon drilled with a hole, that could move transversally in the fuze base. It was maintained at rest in a central position obturating the pyrotechnic line. Under the effect of the centrifugal force during the flight, the lock moved laterally until its central hole was opening the flame communication channel to the detonator.

This sequence is illustrated in the KZ11 Gr fuze scheme aside

Some or all of these safety devices could be combined together, like in the left-hand KZ16.f.10cm.K fuze including, from the top to the bottom :

This created increasingly complex percussion fuzes, hiding a surprising number of components under seemingly simple and rough envelopes, like the EKZ16c fuze below

Percussion fuzes were designed to trigger the burst of the shell when hitting the ground, an obstacle or the aimed target. Originally dedicated to siege guns and projectiles, they became more and more used during the war with all guns including the fieldguns, with the progressive replacement of the classical shrapnell shell for anti-personnal missions by HE shells, inspired by the trench war experience.

Depending on the type of target to be destroyed, it could be necessary to fine tune the precise moment of the explosion in relation with the moment the shell body itself would impact the target.

Yet at the beginning of the war, HE shells fuzes could be equipped with delay systems that would trigger the shell burst some hundredth or tenths of a second after the impact, allowing the shell to perforate a protective coating of concrete, wood or shielding before exploding. During the war, this kind of behavior proved very useful against trenches, deep dug-outs, tanks, or even to create large craters, or to let gaz shells liberate their poison slowly from the ground.

The war experience also induced the fighting armies from each side to feel the need for a percussion fuze that would act so quickly that it would trigger the explosion of the shell before the warhead really entered into the ground or the target. This is how superquick fuzes were invented and mounted on HE shells for anti-personnal, barbed wires destruction or gaz spreading missions.

Non delayed percussion fuzes

Delayed percussion fuzes

|

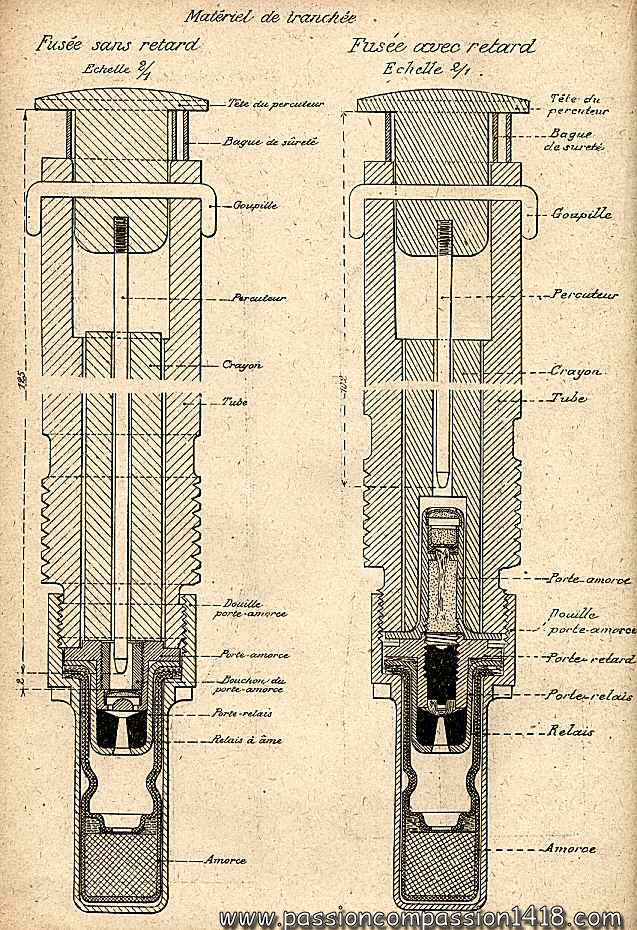

Classical direct action fuzes could prove inefficient when hitting a steel shield or a reinforced concrete surface. In both cases, the shell would burst before it could penetrate into the hard surface, and the shield would be left almost intact. Delaying the fuze action for less then a tenth of a second would let the shell enough time to pierce the shielding and explode behind it or into it, with much more damages. This result could be obtained by inserting a delay (a tiny compressed gunpowder grain) in the classical pyrotechnic line of a percussion fuze, between the graze pellet inertia system and the detonator. This kind of fuze was also found pretty useful with some kinds of gaz shells when the desired effect was that the projectiles digs himself into the ground and slowly liberates its poison for a zone interdiction, against fortresses with perforation shells (with specific fuzes inserted into the shell base to avoid their premature destruction on the concrete), or against tanks. |

| Zoom on the pyrotechnic line of a French 24/31 Mle 94/08 percussion fuze including a small 0.05 sec delay just before the detonator. |

| Whereas French and British fuzes were most of the time originally built with or withour delay, or could be quickly adapted by inserting a delay into the tail, the German engineers wanted to create polyvalent fuzes with selectable delays. This behavior was obtained either by the use of :

Later in war, this kind of complex selection mechanism was less and less used and replaced by delayed or non-delayed fuzes easier to manufacture and to use. |

|

|

|

|

|

| Wartime scheme of a theoretical selectable separate pecussion systems | Wartime scheme of the BdZ10 base fuze delay selection system, based on a single percussion system whose flame could be directed to different channels delayed or not, by the means of an external selector screw. | |

Operation of the selectable separate percussion systems type :

|

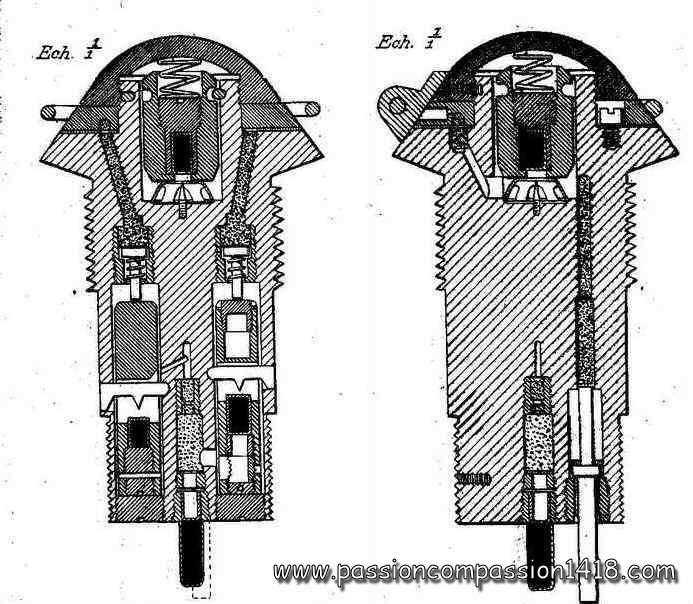

This kind of selectable delay systems gave way to very complex material, as it can be seen on this German percussion fuze with optional delay GrZ04. The left picture shows the inner scheme with the two separate percussion systems, while the right one is a tail view of the same fuze showing the complex inner organization with the holes of the two percussion systems and different safety systems. This complexity was a real handicap in wartime economy, and the new fuzes designed during war were much simplified. |

|

Super-quick percussion fuzes

|

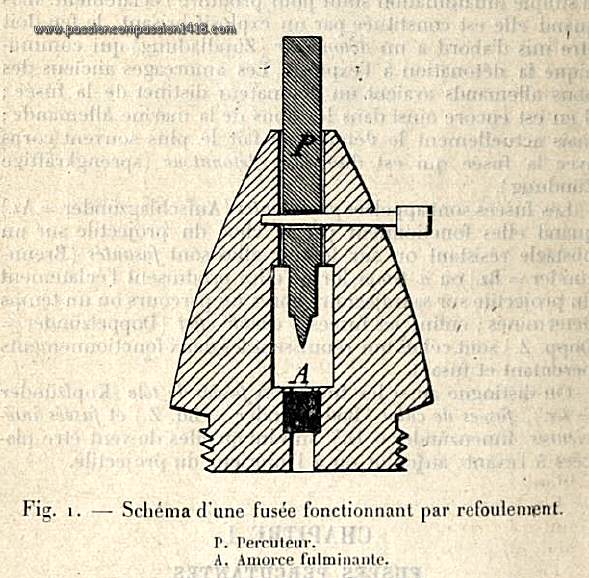

The basics of such a 'push-back fuze' (more often called 'superquick fuze' or 'intantaneous fuze' can be seen on the very simple French mine-thrower fuze on the left, and schematized on the right. In this example, the only safety mechanism is a safety pin that was sheared by the rod when hiiting the target. It is intersting to notice on the left tha a variant existed for this superquick fuze with an additional delay !!! One must remember that in the case of trench artillery the use of sensitive superquick fuzes was dictated by the nature of the grounds and low projectile speeds and not by the need to maximize surface effects. In the other example top left (French I.A. fuze), the long rod has been replaced by a short one, the whole percussion mechanism and pyrotechnics being located on the top of the long fuze, and linked to the shell body via an explosive wire. |

|

|

|

|

| Varitaions of the French superquick fuzes | Theoretical scheme of a typical German superquick fuze, that usually kept an ogival shape, sometimes elongated. | 1917 version of the German Fieldgun superquick fuze 'EKZ17' |

Shrapnel shells were in 1914 the main ammunition in use by the fieldguns of all the fighting nations. Just as with the older fragmentation shells, the efficacity of their anti-personnal effects was dependant of the position they bursted just in front of their target, in order to sprinkle steel fragments and lead balls on it. Since there is no impact of the shell with the target to give the signal for the burst, the fuze had to be a precise mechanism integrating a count down.

The role of the 'time fuzes' devices was to trigger the explosion at the end of a given lapse of projectile flight time (generally from some seconds to almost a minute), corresponding to the distance needed, given the knowledge of the projectile speed.

Pure time fuzes were generally limited to the use of Anti-Aircraft artillery, where one wants the shell to burst around the flying target but where it is important that an unexploded shell does not explode when landing back on friendly land. Most of the time, these systems were associated with a percussion mechanism, making these fuzes 'Time an Percussion' fuzes.

Three main types of time fuzes, were in use during WW1. Two of them were based on the slow and regular combustion of 'pulverine' (compressed gunpowder) track with an approximate speed of 1 cm a second, and the third one appeare lately and was based on clockwork mechanics :

Tubular time fuzes

|

This kind of time fuze was exclusively used by the French artillery, for instance with their famous fuzes '22/31 mod. 1897' (whose wartime scheme is shown at left, and a surviving example at right), or the '30/55 mod.1889'. The following explanation is made for the first model, that was equiped of an additional classic percussion fuze device in its tail. This particular fuze thus was a 'double-effect' (or 'time and percussion') one. |

|

Operation of the tubular time fuzes :

This system, called 'French Time System', was derivated into several fuses models until WW2.

|

|

|

| Fusing spiral groove of a French 25/38 Mle 1880. The lead inner barrel has been pierced at the place of a graduated cap hole | Family picture of several French fuzes derivated from the French Time System, including some pre-WW2 fuzes. | Fusing spiral groove of a 30/55 Mle 1884 French fuze |

Revolving discs time fuzes

Operation of the revolving discs time fuzes :

These fuzes setting was realized prior to the shot by the rotation of a graduated mobile disk, placint the desired flight duration value (in seconds or hectometers) in front of an index engraved in the fix disc or fuze body. Inner parts were designed to immobilize the mobile disc before the shot, in order to prevent it to rotate during the flight under the action of the shell spin forces.

The maximum set-up time could be increased for long range guns in specific fuzes by using a slower burning composition for the gunpowder track, or by increasing the number of discs.

The combustion of all these gunpowder tracks and elements generated smoke, so that multiple windows were machined in those fuzes in order to let the gasses escape.

|

|

|

| Superb section made by Alain Dubois of a British n°80 time and percussion fuze. See the communicating channels between the discs | Revolving discs German HZ05 time and percussion fuze : the destroyed model shows the sliding grooves of the disappeared mobile disc | Opened British n°80 time and percussion fuze, nice view on the central housing where the time pellet was located. |

Clockwork time fuses

An alternative to pyrotechnic systems, entirely mechanical, was also adopted by Germany and France with the rare clockwork fuzes. Indeed, systems based on the burning time of a compressed powder trail had a few drawbacks: